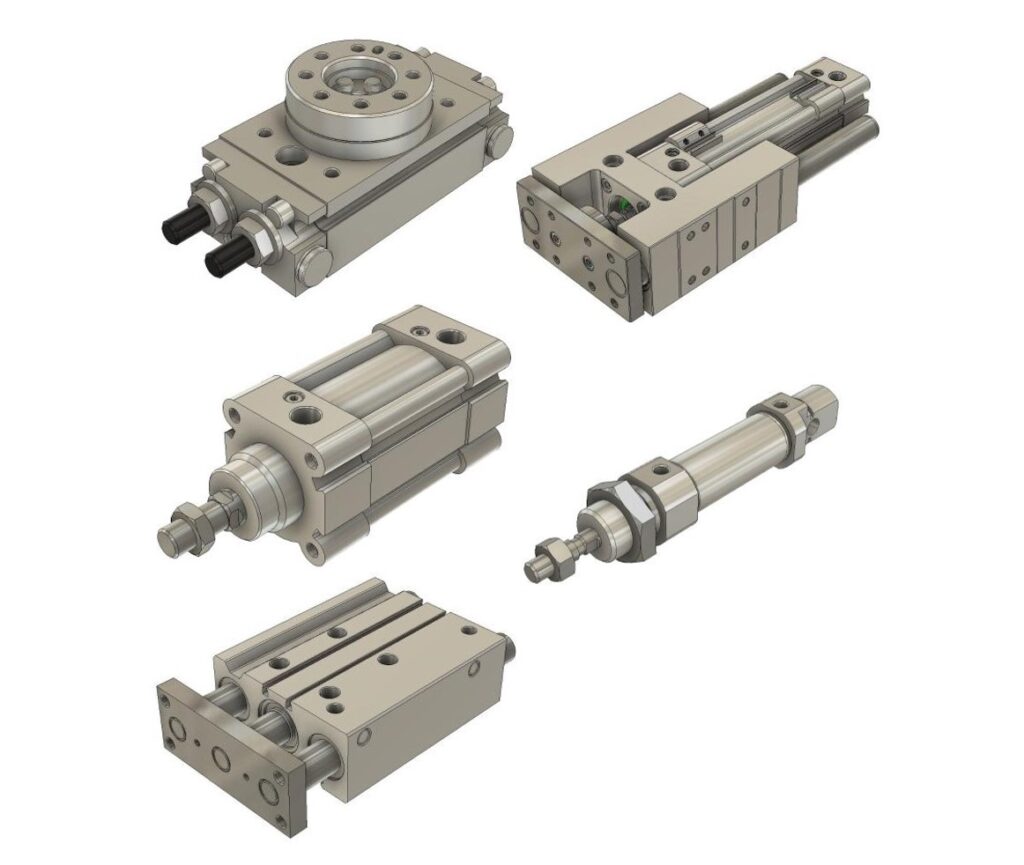

Pneumatic Actuator: Design, types, selection and regulation

How to adjust the cylinder to work long and do not cause machine failure? Selection of actuators, types of equipment and seal protection.

Pneumatic system of machines – Machinery Directive (2006/42/WE)

Principles for the design of safe pneumatic systems taking into account the Machinery Directive (2006/42/WE). What elements go into the basic pneumatic system.

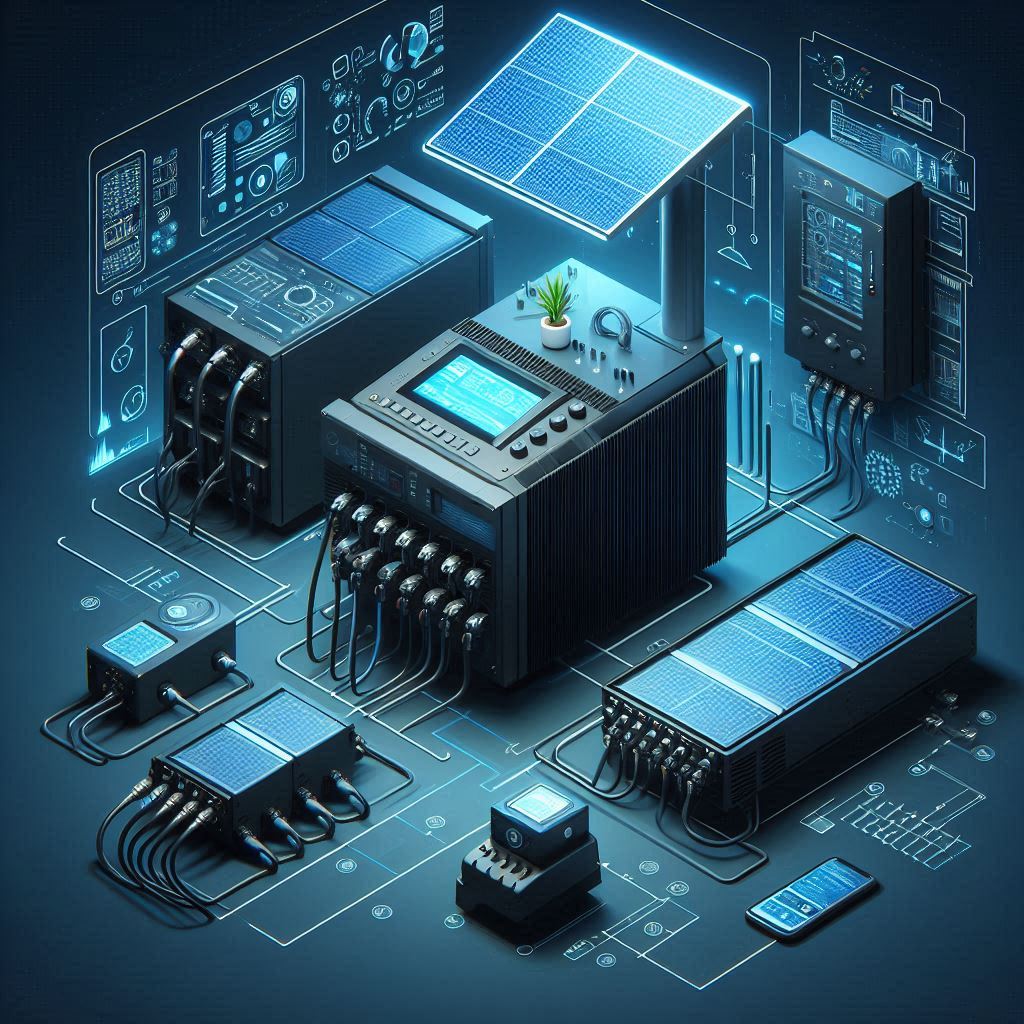

Compressed air – a way to save money

A key way to save compressed air is to reduce the operating pressure from the 6 bar level commonly used in factories in Europe to 4 bar. An example of the effective use of this approach are Japanese companies that have been using reduced pressure in their pneumatic systems for years.

Machine condition monitoring – predictive maintenance

Reducing the number of sensors used, advanced automation technologies, and precise data analysis enable effective machine management and maintenance.

Inverters with Energy Feedback Function to the Grid: Modern Solutions for Industry

Inverters with an energy feedback function to the grid are a modern technical solution that allows for efficient energy management in electric drives. They enable significant energy savings, cost reductions, and reduced environmental impact. Introducing such technologies in manufacturing plants is a step towards sustainable development and long-term economic efficiency.

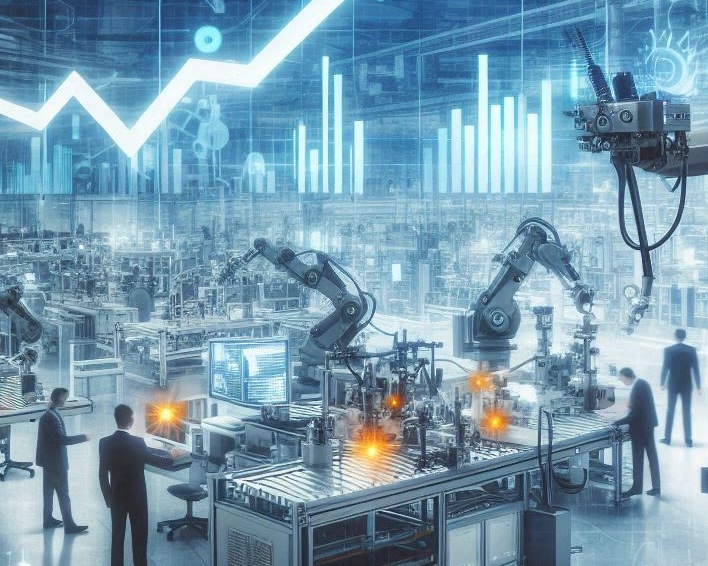

Benefits of Implementing Industry 4.0 in a Business

One of the key advantages of Industry 4.0 is the significant increase in production speed and efficiency. Automated systems and robotics allow tasks to be performed faster and with greater precision than traditional methods. This makes it possible not only to increase the quantity of goods produced in a given time unit but also to maintain high-quality standards. Advanced technologies minimize errors and defects, leading to fewer wastes and complaints.

Industry 5.0 – Industry 4.0 development

A key aspect of Industry 5.0 is the increased role of humans in production processes. While Industry 4.0 sought to maximize automation and minimize human intervention in production, Industry 5.0 focuses on synergistic collaboration between humans and advanced robotic systems. In this model, machines do not replace humans, but support them in performing more complex, creative and decision-making tasks.

Industry 4.0 – direction of development

The main principles of Industry 4.0 include automation, robotics, the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. All these elements aim to increase the efficiency, flexibility, and productivity of manufacturing processes.